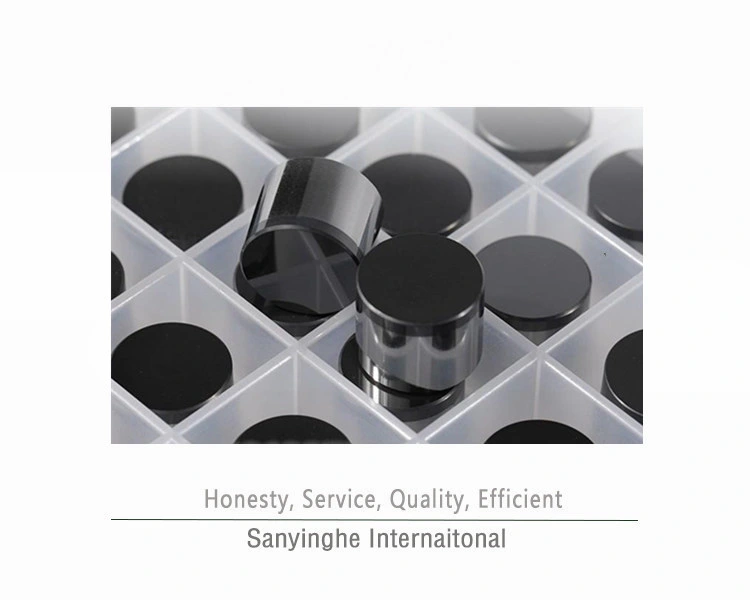

1304 1305 1308 PDC ball inserts drilling tool blade for oil well drilling

PDC cutters(Polycrystalline Diamond Compacts)are made by sintering micron-sized dia-

mond particles onto a tungsten carbide substrate, with the-characters of high hardness

and wear resistance, which can be widely used-for oil drilling, geographical exploration,

coal mining and machinery-processing, etc.

PDC cutter's characters:

1.high impact toughness and wear resistance,

2.service time is 10~20 times longer than normal carbide materials,

3.easy to-weld;

4.heat stability is good below 650ºC, carbonization will turn up above-750ºC and the impa-

ct toughness and wear resistance will be decreased as-well. So the welding temperature should be kept below 650ºC in order to-ensure the product's service time.

| Item | Diameter-D(mm) | Height-H(mm) | Diamond Layper-E(mm) | Diamond Chamfer-α(mm) | Carbide-β(mm) |

| 1308 | 13.44 | 8.00 | 1.80-2.50 | 0.4*45° | 0.50*45º |

| 1313 | 13.44 | 13.20 | 1.80-2.50 | 0.4*45° | 0.50*45º |

| 1608 | 16.00 | 8.00 | 1.80-2.50 | 0.4*45° | 0.50*45º |

| 1613 | 16.00 | 13.20 | 1.80-2.50 | 0.4*45° | 0.50*45º |

| 1616 | 16.00 | 16.00 | 1.80-2.50 | 0.4*45° | 0.50*45º |

| 1908 | 19.05 | 8.00 | 1.80-2.50 | 0.4*45° | 0.50*45º |

| 1913 | 19.05 | 13.20 | 1.80-2.50 | 0.4*45° | 0.50*45º |

| 1916 | 19.05 | 16.00 | 1.80-2.50 | 0.4*45° | 0.50*45º |

| 1919 | 19.05 | 19.00 | 1.80-2.50 | 0.4*45° | 0.50*45º |